Common signs of a worn or failing torsion spring include difficulty in opening or closing the garage door, a noticeable imbalance where one side seems heavier, loud or unusual noises during operation, or visible damage to the spring itself. If you encounter any of these issues, it’s advisable to have your torsion spring inspected and replaced if necessary to avoid accidents.

A Step-by-Step Guide to Torsion Spring Selection

Your garage door’s performance depends on various components; one critical element is the torsion spring. Whether you’re installing a new garage door or replacing an existing spring, making the right choice is essential to ensure your garage door operates smoothly and safely. Follow this step-by-step guide to navigate the process with confidence.

Understanding Torsion Springs

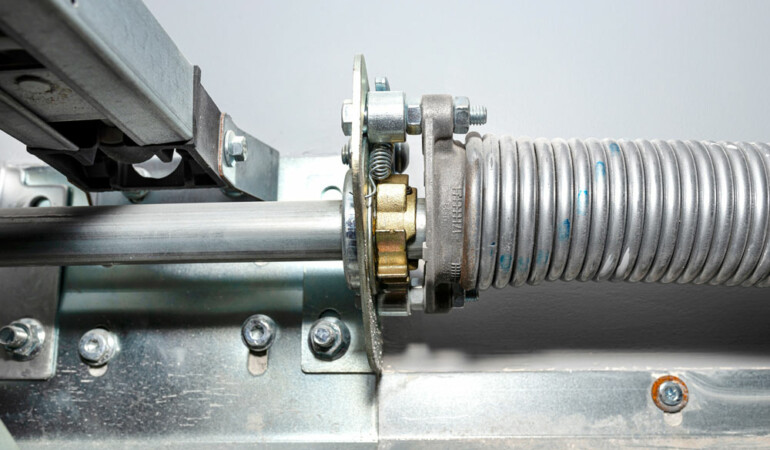

Before diving into the selection process, let’s start with a basic understanding of torsion springs. Torsion springs are tightly wound coils that store and release energy when the garage door operates. They counterbalance the door’s weight, making it easier to open and close. Choosing the right torsion spring involves considering factors such as load requirements, materials, sizing, and safety.

Step 1: Assess Your Garage Door

Check Your Garage Door Type

Begin by identifying the type of garage door you have. Garage doors come in various styles, including sectional, roll-up, and tilt-up. The type of door influences the choice of torsion spring you need.

Measure the Door’s Height and Weight

Accurate measurements are essential. Measure the height and weight of your garage door to determine the force and torque required to lift and lower it. This information will be crucial in selecting the appropriate torsion spring.

Examine Existing Springs (if applicable)

If you’re replacing an existing torsion spring, take note of its specifications. Look for labels or markings that indicate the spring’s dimensions, wire diameter, and other relevant details. This information can serve as a useful reference point.

Step 2: Determine the Required Torque

Calculate the Torque Based on Door Weight

To ensure your garage door is properly balanced, you must calculate the torque required to counteract the door’s weight. Use the formula d = 4 * √(T / (π * K)), where ‘d’ is the wire diameter, ‘T’ is the torque, and ‘K’ is the spring rate. This calculation will help you select the right torsion spring strength.

Account for Safety and Balance

Consider safety and balance when determining torque. A well-balanced garage door reduces the risk of accidents and extends the life of your springs and opener.

Step 3: Material Matters

Choose the Right Material

Select a material that suits your specific needs. Common materials for torsion springs include music wire, stainless steel, carbon steel, and various alloys. Factors such as environmental conditions and corrosion resistance should influence your choice.

Consider Environmental Factors

Think about the environment in which your garage door operates. If it’s exposed to harsh weather conditions or chemicals, opt for a material with superior corrosion resistance.

Step 4: Sizing Your Torsion Spring

Calculate Wire Diameter

Determine the wire diameter based on the torque requirements and spring rate. Adjust the wire diameter to achieve the desired spring strength and performance.

Determine the Spring Rate (K)

Ensure that the spring rate aligns with your application needs. Adjust the number of coils or spring dimensions to achieve the desired spring rate.

Step 5: Configuration and Attachments

Select Leg Configuration

Choose the appropriate leg configuration for your torsion spring. Consider whether you need straight, bent, or hooked legs to ensure secure attachment and efficient torque transfer.

Wind Direction Selection

Specify the winding direction based on your garage door system’s rotation (left-hand or right-hand). The correct winding direction is essential for proper operation.

End Types and Attachments

Select the right end types and attachments to ensure a secure and stable connection between the spring and the garage door system.

Step 6: Temperature and Durability

Evaluate Working Temperature

Consider the temperature range in which your garage door operates. Ensure the selected material can withstand these conditions without compromising performance.

Assess Durability and Fatigue Life

Calculate the expected number of cycles and evaluate the torsion spring’s fatigue life to ensure it meets your application’s demands.

Step 7: Safety First

Apply the Appropriate Safety Factor

Always apply an appropriate safety factor to your calculations to account for uncertainties and variations in loads. Safety should be a top priority when selecting a torsion spring.

Step 8: Seek Expert Advice

If you’re unsure about any aspect of torsion spring selection or if you have specialized needs, don’t hesitate to seek expert advice. Consult with a professional or contact Fix Garage Doors CA at (905) 247-6699 for tailored guidance.

Conclusion

Creating a table of different torsion springs can be quite detailed and specific, as numerous variations are available to suit various applications. Below is a simplified table to give you an idea of the differences you might encounter when selecting torsion springs. Keep in mind that specific dimensions, materials, and other characteristics will vary depending on your unique needs and the manufacturer’s specifications:

| Torsion Spring Type | Key Features | Common Applications |

|---|---|---|

| Standard Torsion Spring | Helical wound coils | Residential garage doors |

| Various wire diameters and lengths | Commercial roll-up doors | |

| Left-hand or right-hand windings | Industrial machinery | |

| Different leg configurations (e.g., straight, bent, hooked) | Agricultural equipment | |

| Automotive applications | ||

| Stainless Steel Torsion Spring | Made from stainless steel for corrosion resistance | Coastal areas with salt air |

| Suitable for humid or corrosive environments | Food processing equipment | |

| High durability and longevity | Pharmaceutical manufacturing | |

| Available in various grades | Chemical processing | |

| High-Cycle Torsion Spring | Designed for extended cycle life | High-traffic commercial doors |

| Specialized materials and coatings | Parking garages and toll booths | |

| Enhanced fatigue resistance | Secure storage facilities | |

| Precision manufacturing | Emergency vehicle bays | |

| Torque Master Spring | Concealed within a tube or barrel | Residential garage doors (space-saving) |

| Reduction in exposed parts for safety | Limited clearance or low headroom doors | |

| Customizable to fit various door types | Aesthetically pleasing design | |

| Less maintenance required | Noise-sensitive environments | |

| Custom Torsion Spring | Tailored to specific dimensions and requirements | Unique or specialized applications |

| Wide range of materials and coatings available | Prototypes and custom machinery | |

| Designed to meet precise load and deflection specifications | Aerospace and defence | |

| Medical devices and equipment |

Please note that this table provides a general overview of different torsion spring types and their common applications. When selecting a torsion spring, it’s essential to consult with a manufacturer or supplier to ensure the spring’s specifications align with your specific needs and requirements.

Selecting the right torsion spring for your garage door is a critical decision that affects its performance, safety, and longevity. By following this step-by-step guide and considering factors like load requirements, materials, sizing, and safety, you can confidently choose the perfect torsion spring for your needs. For expert assistance and top-quality garage door services in Toronto, Barrie, Mississauga, Markham and surrounding areas, trust Fix Garage Doors CA to keep your garage door operating flawlessly.

Date of page creation: September 13, 2023

Page update date: November 21, 2023

Frequently Asked Questions

What are the signs that my garage door's torsion spring needs replacement?

Can I replace my garage door's torsion spring myself, or should I hire a professional?

While some experienced individuals may attempt a DIY torsion spring replacement, it can be extremely dangerous due to the high tension involved. It’s highly recommended to hire a professional garage door technician for this task. They have the expertise, tools, and safety equipment to ensure a safe and proper installation. Attempting to replace a torsion spring without the necessary knowledge and equipment can lead to serious injuries or further damage.

Are there any maintenance tips to extend the lifespan of my torsion spring and garage door?

Yes, regular maintenance can prolong the life of your torsion spring and garage door. Lubricate the springs, rollers, and hinges periodically to reduce friction. Inspect and tighten all bolts and fasteners. Keep the tracks clean and free of debris. Also, perform a visual inspection of the springs and cables for signs of wear or damage. Consider scheduling professional maintenance at least once a year to ensure everything is in optimal condition and prevent unexpected issues.